This was posted on 2018-08-17

The project is aimed at measuring the flow rate of the fabric panels/ partially stitched garments in a conventional production line. This will fundamentally help in the following

- Allowing operator to understand personal performance

- Allowing the line manager to carry out efficient line balancing

- Measuring performance of production lines and alarming slow downs

- Measuring WIP and alarming abnormal increases

The current method of measuring SMV is not real time. A member of the production team will visit the production line with a stopwatch to measure the time between operations. The operator will not have an indication of his/her performance.

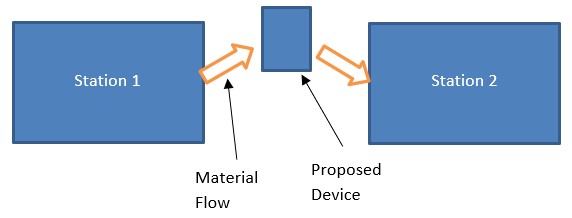

The solution proposed will consist of a weight measuring tray that will be calibrated for a specified number of garments before the start of the process. The time between adding garments to the tray from the operator from the prior process and removing garments from the tray from the operator in the later process will be calculated.

The information gathered will be filtered to obtain average values of the time difference and the time difference will be displayed on the interface. The display on the right will show the average time between removing a garments while the display on the left will show the average time between adding garments.

| Scenario | # of Operators | WIP | Flow | Description | Step | Stack 1 | Machine 1 in Progress | Stack 2 | Machine 2 in Progress | Stack 3 | Comment | ||||||

| Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â |

| 1 | 2 | N/A | Single Piece | Normal Operation - Forward Flow | 1 | 10 | Â | 0 | Â | 10 | Â | 1 | Â | 10 | Â | ||

| 2 | 9 | → | 1 |  | 10 |  | 1 |  | 10 |  | |||||||

| 3 | 9 |  | 1 |  | 10 |  | 0 | → | 11 |  | |||||||

| Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â |

| 2 | 1 | 3 | Unit Flow | Same Operator - No orientation change when moving to next operaton | 1 | 10 | Â | 0 | Â | 10 | Â | 0 | Â | 10 | Â | ||

| 2 | 9 | → | 1 |  | 10 |  | 0 |  | 10 |  | |||||||

| 3 | 9 |  | 0 | → | 11 |  | 0 |  | 10 |  | |||||||

| 4 | 8 | → | 1 |  | 11 |  | 0 |  | 10 |  | |||||||

| 5 | 8 |  | 0 | → | 12 |  | 0 |  | 10 |  | |||||||

| 6 | 7 | → | 1 |  | 12 |  | 0 |  | 10 |  | |||||||

| 7 | 7 |  | 0 | → | 13 |  | 0 |  | 10 |  | |||||||

| 8 | 7 |  | 0 |  | 12 | → | 1 |  | 10 |  | |||||||

| 9 | 7 | Â | 0 | Â | 12 | Â | 0 | Â | 11 | Â | |||||||

| Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â |

| 3 | 1 | 3 | Unit Flow | Same Operator - No Orientation Change - Operator will collec finished garments and then drop to dispose together | 1 | 10 | Â | 0 | Â | 10 | Â | 0 | Â | 10 | Â | ||

| 2 | 9 | → | 1 |  | 10 |  | 0 |  | 10 |  | |||||||

| 3 | 8 | → | 2 |  | 10 |  | 0 |  | 10 |  | |||||||

| 4 | 7 | → | 3 |  | 10 |  | 0 |  | 10 |  | |||||||

| 5 | 7 |  | 0 | → | 13 |  | 0 |  | 10 |  | |||||||

| 6 | 7 |  | 0 |  | 12 | → | 1 |  | 10 |  | |||||||

| 7 | 7 |  | 0 |  | 12 |  | 0 | → | 11 |  | |||||||

| Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â |

| 4 | 1 | 3 | Unit Flow | Same Operator - Orientation required when moving to next operator | 1 | 10 | Â | 0 | Â | 0 | Â | 0 | Â | 0 | Â | 10 | Â |

| 2 | 9 | → | 1 |  | 0 |  | 0 |  | 0 |  | 10 |  | |||||

| 3 | 9 |  | 0 | → | 1 |  | 0 |  | 0 |  | 10 |  | |||||

| 4 | 8 | → | 1 |  | 1 |  | 0 |  | 0 |  | 10 |  | |||||

| 5 | 8 |  | 0 | → | 2 |  | 0 |  | 0 |  | 10 |  | |||||

| 6 | 7 | → | 1 |  | 2 |  | 0 |  | 0 |  | 10 |  | |||||

| 7 | 7 |  | 0 | → | 3 |  | 0 |  | 0 |  | 10 |  | |||||

| 8 | 7 |  | 0 |  | 0 | → | 3 |  | 0 |  | 10 |  | |||||

| 9 | 7 |  | 0 |  | 0 |  | 2 | → | 1 |  | 10 |  | |||||

| 10 | 7 | Â | 0 | Â | 0 | Â | 2 | Â | 0 | Â | 11 | Â | |||||

| Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â |

| 5 | 2 | 3 | Unit Flow | 1st Operator does 2 garments and half of the 3rd garment. 2nd operator does the rest | 1 | 10 | Â | 0 | Â | 10 | Â | 0 | Â | 0 | Â | ||

| 2 | 9 | → | 1 |  | 10 |  | 0 |  | 0 |  | |||||||

| 3 | 9 |  | 0 | → | 11 |  | 0 |  | 0 |  | |||||||

| 4 | 8 | → | 1 |  | 11 |  | 0 |  | 0 |  | |||||||

| 5 | 8 |  | 0 | → | 12 |  | 0 |  | 0 |  | |||||||

| 6 | 7 | → | 1 |  | 12 |  | 0 |  | 0 |  | |||||||

| 7 | 7 | Â | 1 | Â | 12 | Â | 0 | Â | 0 | Garment waititng for next Operator | |||||||

| 8 | 7 |  | 0 | → | 13 |  | 0 |  | 0 |  | |||||||

| Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â |

| 6 | 1 | 3 | Unit Flow | Defect Occurs in second Garment and gets inserted in the next cycle | 1 | 10 | Â | 0 | Â | 0 | Â | 0 | Â | 10 | Â | ||

| 2 | 9 | → | 1 |  | 0 |  | 0 |  | 10 |  | |||||||

| 3 | 9 |  | 0 | → | 1 |  | 0 |  | 10 |  | |||||||

| 4 | 8 | → | 1 |  | 1 |  | 0 |  | 10 |  | |||||||

| 5 | 8 |  | 0 | ↑ | 1 |  | 0 |  | 10 | Defect Handed Over Supervisor | |||||||

| 6 | 7 | → | 2 |  | 1 |  | 0 |  | 10 |  | |||||||

| 7 | 7 |  | 1 | → | 2 |  | 0 |  | 10 |  | |||||||

| 8 | 6 | → | 2 |  | 2 |  | 0 |  | 10 |  | |||||||

| 9 | 6 |  | 1 | → | 3 |  | 0 |  | 10 |  | |||||||

| 10 | 6 |  | 1 |  | 2 | → | 1 |  | 10 |  | |||||||

| 11 | 6 |  | 1 |  | 2 |  | 0 | → | 11 |  | |||||||

| 12 | 6 |  | 1 |  | 1 | → | 1 |  | 11 |  | |||||||

| 13 | 6 |  | 1 |  | 1 |  | 0 | → | 12 |  | |||||||

| 14 | 6 |  | 1 |  | 0 | → | 1 |  | 12 |  | |||||||

| 15 | 6 |  | 1 |  | 0 |  | 0 | → | 13 |  | |||||||

| 16 | 5 | → | 2 |  | 0 |  | 0 |  | 13 |  | |||||||

| 17 | 5 |  | 1 | → | 1 |  | 0 |  | 13 |  | |||||||

| 18 | 4 | → | 1 | ↓ | 2 |  | 0 |  | 13 | Defect Corrected & Returned | |||||||

| 19 | 4 |  | 0 | → | 3 |  | 0 |  | 13 |  | |||||||

| 20 | 4 |  | 0 |  | 2 | → | 1 |  | 13 |  | |||||||

| 21 | 4 |  | 0 |  | 2 |  | 0 | → | 14 |  | |||||||

| Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â |

| 7 | 1 | 3 | Unit Flow | Defect Occurs in second Garment and gets inserted in the same cycle | 1 | 10 |  | 0 |  | 0 |  | 0 |  | 10 |  | ||

| 2 | 9 | → | 1 |  | 0 |  | 0 |  | 10 |  | |||||||

| 3 | 9 |  | 0 | → | 1 |  | 0 |  | 10 |  | |||||||

| 4 | 8 | → | 1 |  | 1 |  | 0 |  | 10 |  | |||||||

| 5 | 8 |  | 0 | ↑ | 1 |  | 0 |  | 10 | Defect Handed Over Supervisor | |||||||

| 6 | 7 | → | 2 |  | 1 |  | 0 |  | 10 |  | |||||||

| 7 | 7 |  | 1 | → | 2 |  | 0 |  | 10 |  | |||||||

| 8 | 6 | → | 2 |  | 2 |  | 0 |  | 10 |  | |||||||

| 9 | 6 |  | 1 | → | 3 |  | 0 |  | 10 |  | |||||||

| 10 | 6 |  | 1 |  | 2 | → | 1 |  | 10 |  | |||||||

| 11 | 6 |  | 1 |  | 2 |  | 0 | → | 11 |  | |||||||

| 12 | 6 |  | 1 | ↓ | 2 | → | 1 |  | 11 | Defect Corrected & Returned | |||||||

| 13 | 6 |  | 0 |  | 2 |  | 0 | → | 12 |  | |||||||

| 14 | 6 |  | 0 |  | 1 | → | 1 |  | 12 |  | |||||||

| 15 | 6 |  | 0 |  | 1 |  | 0 | → | 13 |  | |||||||

| 16 | 5 | → | 1 |  | 1 |  | 0 |  | 13 |  | |||||||

| 17 | 5 |  | 0 | → | 2 |  | 0 |  | 13 |  | |||||||

| 18 | 4 | → | 1 |  | 2 |  | 0 |  | 13 |  | |||||||

| 19 | 4 |  | 0 | → | 3 |  | 0 |  | 13 |  | |||||||

| 20 | 4 |  | 0 |  | 2 | → | 1 |  | 13 |  | |||||||

| 21 | 4 |  | 0 |  | 2 |  | 0 | → | 14 |  | |||||||

| Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â | Â |

| 8 | 3 | N/A | Single Piece | First machine has 2 operatos who do the same garment partially | 1 | 10 | Â | 0 | Â | 10 | Â | Â | Â | Â | Â | ||

| 2 | 9 | → | 1 |  | 10 |  |  |  |  |  | |||||||

| 3 | 9 |  | 0 | → | 11 |  |  |  |  |  | |||||||

| 4 | 8 | → | 1 |  | 11 |  |  |  |  |  | |||||||

| 5 | 8 |  | 1 | ↑ | 11 |  |  |  |  |  | |||||||

| 6 | 7 | → | 2 |  | 11 |  |  |  |  |  | |||||||

| 7 | 7 |  | 1 | → | 12 |  |  |  |  |  | |||||||

| 8 | 6 | → | 2 |  | 12 |  |  |  |  |  | |||||||

| 9 | 6 |  | 1 | → | 13 |  |  |  |  |  | |||||||

| 10 | 5 | → | 2 |  | 13 |  |  |  |  |  | |||||||

| 11 | 5 |  | 1 | → | 14 |  |  |  |  |  | |||||||

| 12 | 4 | → | 2 |  | 14 |  |  |  |  |  | |||||||

| 13 | 4 |  | 1 | → | 15 |  |  |  |  |  | |||||||

| 14 | 3 | → | 2 |  | 15 |  |  |  |  |  | |||||||

| 15 | 3 |  | 1 | ↓ | 16 |  |  |  |  |  | |||||||

| 16 | 3 |  | 0 | → | 17 |  |  |  |  |  | |||||||

| 17 | 2 | → | 1 |  | 17 |  |  |  |  |  | |||||||

| 18 | 2 |  | 0 | → | 18 |  |  |  |  |  | |||||||