This was posted on 2024-03-07

John Samarasinghe | experience to date of writing

- Automation Engineer @ twinery / MAS Innovations (Innovation arm of MAS) (2016 – 2021)

- Automation lead for the impleentation of process standardization, optimization and automation solutions to MAS Leisureline

- Part of the team for the successful implementation of Production Engineering to MAS Bodyline

- Business Analyst @ MAS Active. Reporting to Director of Process Excellence to oversee Production Engineering, Automation and MOS (2021)

- Senior Business Analyst @ MAS Active. Reporting to the Director of Manufacturing to oversee the Operations of 5 MAS Active Cut & Sew Manufacting Plants (MAS Shadowline, Contourline, Sleekline, Asialine, Mamadala) (2022 – 2023)

- Assistant Manager - Special Projects @ MAS Active. Reporting to the Director of Manufacturing to oversee projects aimed at elevating the operations and automation of the MAS cut & Sew Manufactruing Plants (2022)

- McKinsey Young Lead for implementing long term automated solutions into MAS Operations (2022)

When to automate

Having worked in the central automation arm of MAS for a number of years I have worked in a number of grand automation solutions ranging from automating the boxer leg hems to simple pick and place operations. However, with many of these automation solutions we had failed many times and sunk thousands of dollars in automation cost. It took the team many cycles to understand some basics to understand why this was happening.

One example of this is my work on the automation of the intimate underwear gusset attach operation which included gathering and stitching 3 loose panels on an overlock sewing machine. When this automation started we were to achieve a cycle time of about 20 seconds to be better than manual operators in a certain plant. This operation had many issues starting with handling lose fabric to balancing the stitch such that 3 panels of varying length are equally stretched to the same length. After many months and many, many iterations later we finally achieved a solution which took about 30 seconds. We were happy to have achieved the functionality of the operation closer to the cycle time. However, this was was very short as were quickly introduced to another plant in the same company which has manual operators who achieve a cycle time of less than 7 seconds with better quality than our automation.

There are a number of steps that need to be performed before stepping in to automation. It was introduced to be as a 3 step process as below. Although this is mostly used in high labour intensive operations, I belive it is applicable universally.

1. STANDARDIZE

- Ensure your operation is standard or better than the current best known publicly

- Ensure your operation is standard across all operators in your plant and is the current best

- Ensure your operation is standard across all plants and is the current best

2. OPTIMIZE

- Optimize your operation with the best practices available in the organization and outside the organization

- Optimize your operation with the improvements introduced by mature operators who are familiar with the operation

- Optimize your operation with the best practices applicable from similar operations

3. AUTOMATE

Once your have a standard operation across multiple operators and multiple plants and you eliminated all non-value added waste through optimization you are ready to automate the operation with higher payback due to standardization and longer applicability due to following the current best.

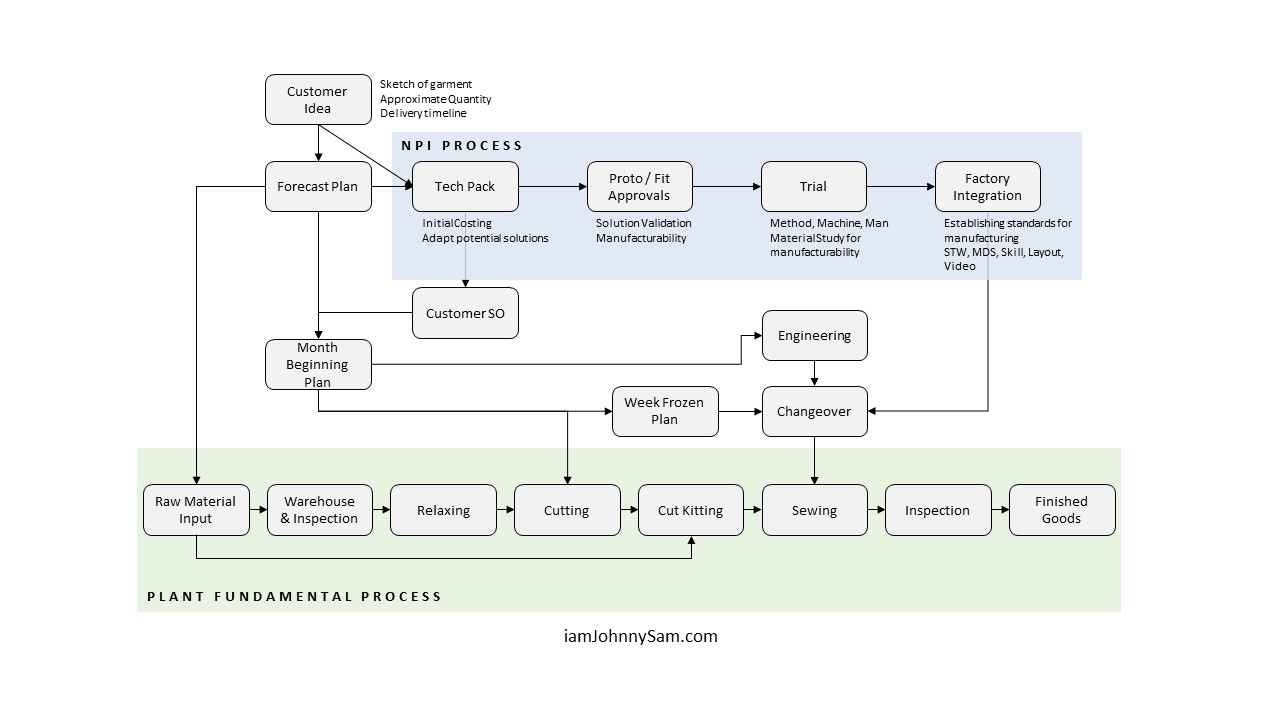

The Journey from Fabric to Appael

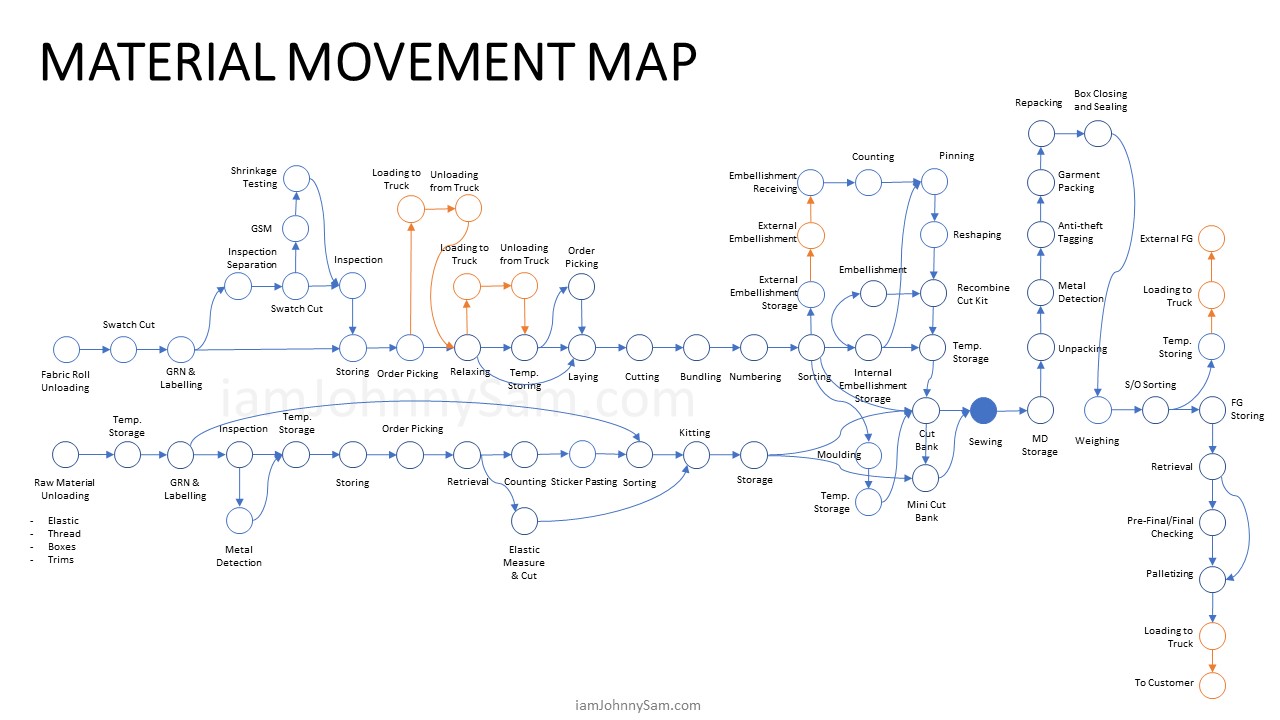

In the image below I have summarized the standard fabric movement paths applicable for most manufacting plants.

The image above can be broken down in to 3 major sections.

- Pre Sewing

- Sewing

- Post Sewing

For the journey which takes a number of days to weeks in a standard process, the sewing operation which is the value added operation will only take roughly 10 minutes whereas the Pre and Post sewing operations are mostly non-value added to the customer and take up majority of the time and a signoficant manpower. This area should be a consideration for the Standardize, Optimize & Automate formula.

Automating the sewing operation is the most beneficial to your plant as improvements in this value adding process directly impact your bottom line. But before that we must understand of how the operation is planned. Capacity is key.

Capacity Planning

Your sewing process is goverened by capacity. It can be divided to three.

- Available Capacity - Total Clock Hours

- Planned Capacity - Standard Available Hours

- Output Capacity - Standard Produced Hours

In your plant there are headcount who are directly contributing to the value adding process (Direct headcount). We must make sure this headcount is always fulfiled using a slack / back-up headcount as if this cadre falls short your entire plant capacity will drop. The slack percentage is usually equal to the absenteeism of the plant. There is another training headcount who will be going through training to be added to the value adding headcount. The percentage of members in this headcount is equal to the value adding member turnover of the plant.

Clock Hours = Working hours of Employees directly contributing to value adding process

When these employees come to work they will be clocking in and clocking out. During this time they will be contributing to your capacity.

Standard Hours Available = Clock Hours * Plant Historic EfficiencyStandard Hours Produced = Planned Time per piece * Number of pieces producedEfficiency = Standard Hours Produced / Total Clocked HoursExample ABC T-shirt Manufacuring Company

|

Total Lines |

10 |

Lines |

|

Planned Headcount per Line |

6 |

Members |

|

Total Direct Headcount |

10 * 6 = 60 |

Members |

|

Slack / Back-up Headcount |

10 |

Members |

|

Total Value adding members available. |

70 |

Members |

If calculations are correct. The total headcount on any given day should be 60 since you are always expecting 10 members to be absent.

|

Working Hours |

8 |

Hours |

|

Clock Hours per day |

60 * 8 = 480 |

Hours |

|

Historic Efficiency of the plant |

65 |

% |

|

Standard Hours |

312 |

SAH |

|

Total Time to make 1 T-shirt |

2 |

minutes |

|

Estimated T-shirt ourput per day |

9,360 |

pieces |

|

Number of additional Value adding members attended in certain day |

8 |

Members |

Example during 1 day

|

Line |

Pieces Per Day |

Clock Hours |

Standard Hours Produced |

Line Efficiency |

|

1 |

900 |

48 |

30 |

63% |

|

2 |

700 |

48 |

23 |

49% |

|

3 |

670 |

48 |

22 |

47% |

|

4 |

500 |

48 |

17 |

35% |

|

5 |

950 |

48 |

32 |

67% |

|

6 |

800 |

48 |

27 |

56% |

|

7 |

850 |

48 |

28 |

58% |

|

8 |

790 |

48 |

26 |

54% |

|

9 |

830 |

48 |

28 |

58% |

|

10 |

400 |

48 |

13 |

27% |

|

Total Standard hours produced |

246 |

SAH |

|

Total Clocked hours of members in line |

480 |

Hours |

|

Clocked hours by additional members from slack who came to work (8 members) |

64 |

Hours |

|

Total Value Added Clocked Hours |

544 |

Hours |

|

Plant Effieciency |

45 |

% |

Time per garment calculation

As you can see the Standard hours produced is governed by the time we set for the garment to be manufactured and not the actual time that it took for the garment to be manufactured. This is because in the industry there is a pre-defined time for each manufacturing operation defined by the best practices of the plant. It is important that this time to garment calculation is made standard and proliferated to all members of the plant so all members know how to perform the operation in order to achieve this defined time.

Standard Minute is the time value arrived at for a task based on the average rate of output which qualified workers will naturally achieve without over exertion provided that they know and adhere to the specified method and provided that they are motivated to apply themselves to their work.

Each operation in apparel manufacturing value adding processes has a defined (not fixed) Standard Minute Value (SMV). The SMV is calculated using 2 methods. (Standard Minute Value (SMV): Definition, Calculation and Use (onlineclothingstudy.com))

Manual Calculation:

- ?Record Observed time (Cycle time)

- Convert observed time into Basic time (Based on experience

Basic Minute = Observed Time * Performance Rating- Apply Applicable allowances

- Calculate standard minute

Standard Minute Value = Basic Minute + Bundle Allowances + Machine Allowances + Personal Fatigue AllowancesScientific Method:

Breakdown the operation into basic motions which are identified by pre-defined motion codes. Apply time value allocated to the predefined motion code.

PMTS software

- GSD Cost

- SewEasy

- ProSMV

In these codes, allowances are already captured as follows.

- 1% - Machine Machine Start-up, Shut Down, Adjustments, Cleaning

- 2% - Contingency Unavoidable Delays and Minor extra work

- 11% - Relaxation

- 4% Fatigue - Physiological and psychological relaxation

- 7% Personal – Water break, Washroom

ChangeOver Losses

Changeover losses account for one of the largest types of losses in the production floor. When 1 style in your production line has completed, the process of changing over your line to a new style and ramping up your production to previous efficiencies include a large amount of output loss.

Before you automate the inefficiencies in changeover process you must ask;

- Is there a frame alignment between the previous and next garment? Many similar operations exisit to prevent training time

- Is the planned ramp up plan being achieved?

- Can you plan the production plan better to prevent changeover or minimize the changeover ramp up?

Commonly used KPIs

Before automating in the apparel industry, it is also helpful to understand the KPI's in the factoryas they will give you a understanding of the current goals/pain points of the factory and where they are actively looking for improvement.

Data Analytics

When you want to improve the productivity of a system or a plant data analytics is your friend. The more granular you can capture your data, the better you can drill down in to the root cause of problems in your production as well as identify and track areas of improvement.

Investing some money in to data analytics using sensors, monitoring tools and simple processes can help your plant unlock larger hidden improvements which will help you recover your investment in very short amount of time.

Here are some examples of what you can track and what you can do with it.

- Production Output

- Identify low perfoming lines

- Identify training requirements

- Downtime

- Employee movement

- Identify lines with operator conducted improvement initiatives

- Visibility on Plan-to-Performance metrics

- In-line, End-line and Quality output

- Identify training requirements

- Identify machine improvements

- Machine tracking

- Better utilization of sewing machines across the plant

- Maintenance tracking

- Automation installtion tracking

- Machine availability tracking by linking to production plan

Pre- and Post-Sewing Automation

In the current trend of having a journey to the Factory of the Future it is important to nail down an efficient pre- and post-sewing process. What should you consider when attempting Pre- and Post-Sewing automation?

- Keep payback calculations anchored to the company bottomline to see tangible benefits.

- Roll out common solutions and existing best practices available in the plant to other similar processes immediately.

- Use economies of scale to introduce solutions across multiple similar operations or multiple plants to bring cost down

Automations Assessment Critera

- Raw material cost reduction to reduce product cost

- Operatinal cost reduction to reduce plant operating costs

- Floor space reduction for the expansion of Value adding processes and improving plant capacity an reducing plant & product cost

- Process Leadtime improvements to make plant attractive to customer

- Ergonomic Improvements to make plant attractive to employees

- Employee redeployment to value adding processes by eliminating / reducing labour dependance

- Technology readiness level. How mature is the automated solution.

Automation Suggestions

- Overall

- Plant re-arrangement to make fabric movement streamlined.

- Raw Material Warehouse

- Automated Fabric Roll Unloading using collapsible / telescopic conveyors

- Swatch cut tools

- Fabric color extractors

- Automated GSM measurement without cutting

- Optimized roll storage for space optimization

- Pigeon hole fabric storage for ergonomic retrival of heavy fabric which can be weighed down by other fabric stacked on top.

- Ergonomic lifting tools for fabric roll handling process

-

- Put-to-light and Pick-to-light systems for speeding up storage and retrieval

- Augmented Reality assiting tools

- Automated fabric relaxing machines

- Sorting conveyors

- Automated inspection vision systems

- ASRS systems

- Cutting

- Fabric laying automation

- Cutting fabric waste reduction at QA and Fabric Cutting process

- Fabric cutting automation

- Automated Fabric bundling after cutting

- Panel numbering machines

- Automated elastic cutting machines

- Automated elasting cutting and ring making machines

- Cut Bank

- AGV / Conveyors for milkrun automation

- Automated Fabric / Cut kit storage and retrieval

- Put-to-light and Pick-to-light systems for speeding up storage and retrieval

- Pick Assisting tools

- Finished Goods Warehouse

- Telescopic conveyors for goods transport to and from trucks

- Automated coveyor weighing solutions

- Palletizing Robots

- Automated carton labeling

- RFID Counting for apparel equipped with RFID tags

- Automatic secrutiy tag applicators

Production Improvements prior to Automation

Areas to focus:

- Improve Garment SMV

- Minimize changeover-loss

- Increase utilization of machines

- Deskill operations and consistency in quality

- Improve throughput time

- Minimize balancing loss

- Reduce garment touchpoints

- Support the production line leads structure

Focused Layout Improvements

- BASIC LAYOUT

- Review and optimize the operations and sequence in GSD and transfer the finalized SMV to the module

- STANDARDIZED LAYOUT

- Review and optimize the operations & sequence based on GSD and analyze it for best possible method

- Use attachments and demarcations for workplace arrangement

- Consider pick up and disposal methods incorporating material flow

- Use work combination charts for further improvements

- OPTIMIZED LAYOUT: once we standardize layout then we need to find the right size / optimum layout size

- Main / Sub Assembly Layouts - Identify product wise component that we can separate from the line and operate as sub assembly and connect the material flow

- Chassis base layout / sections - Align layout with the chassis [Primary and Secondary chassis] also you can separate production floor to Chassis zone.

- Cells - Re design layout as Dancing cells

- MPC [Multi Product Cell] - Design cell where you can product Multi products

Focused Needlepoint Improvements

Man

- IE skill development (GSD practitioner training)

- Director, General Manager, Factory Manager and middle management familiarization of GSD

- Team member skill development

Machine

- Safety

- Machine standardization and application of all options

- Incremental autonomations

- Possible machine upgrade (e.g., Auto choppers for DN)

- Special machine attachments (gauges / foots etc.)

Method

- Maximum working area to normal working area

- Workplace demarcation (to improve muscle memory)

- Work elemental analysis of operating time

- Continuous improvement of the cycle time

- Identify main assembly and sub assembly operations

- Plan total SMV for total manning

Sewing Automation

Drive Operator standardization

- Auto stitching devices by controlling the stitch rate. Operator requires to guide. Automation will control the cycle time through RPM, Presser foot control and Trim signalling.

- Provides line leads visibility to training requirements of operators

Reduce Non-value adding motions

Within a larger value adding process such as Sewing there are many non-value adding motions which can be reduced to better utilize the time

- CUT

- Removing cutting operation by using autocutters

- SHORT-THREAD-TRIMMER-DEVICES.pdf (jukiindia.com)

- Automatic Thread Trimmer – A Timeless Feature | Juki (jukieurope.com)

- FOOT

- Auto Foot control

- Anticurling Devices

- Tag Feeding

- Auto Counters

Utilizing existing automated machinery

Where possible immediately transition operations done by manual machines like single needle machines to pattern sewers and bartack machines using jigs and fixtures to hold the fabric in place. These machines are already tested and available solutions which can easily offload the operators time to loading multiple machines while the machine takes care of the stitch.

- Electrical Sewing Machine Manufacturer,Automatic Sewing Machine Supplier,Exporter (guankiauto.com)

- Special Sewing Machine Manufacturer and Supplier,Special Sewing Machine Exporter (guankiauto.com)

- Automatic Sewing Machine Manufacturer and Supplier,Automatic Sewing Machine Exporter (guankiauto.com)

Utilizing existing accessories

Using folders and Jigs

This is a quick way of boosting up your line productivity by freeing up operator time in aligning and matching.

Utilizing Fixtures and tools for uplifting ergonomics

- Reduce the operators movements by utilizing certain fixtures and stands such that all raw material and tools are within the operators working space.

- Using Ergonomic mats for standing

- Automating labour intensive tasks such as Bra wire insertion

Modular Manufacturing

By breaking down your operations to the most basic motions you are able to create standard and repeatable construction patters. Whenever a new style is introduced to your plant you are able to use these repeatable modules to reconstruct the garment from the ground up. This allows your plant to maintain machine layouts and operators also in a modular approach thus minimizing the changeover time.

A garment construction tree is useful here.

Cell Manufacturing

When there are processes that are common across large number of products in your plant and is not reliant on the production process, it is beneficial to eliminate this process from the critical path and move this process as a collective operation to the pre-sewing area.

An example of this is the elastic ring making process. Elastic rings can be fabricated in bulk for all lines using the same raw material. By moving this operation to a seperate cell and including the prepared elastic rings in to the cut bundle we can save time in the critical path. At the same time we can fully automate the ring making process since the operation is highly repetitive.

Change-over Improvements

- Mechanic Improvements

- Providing the mechanic with jigs, auto calibration systems and devices to speed up the mechanics machine set up time. Including these calibrated values in the changeover sheet will help the mechanic has a quantitive approach to the machine set up to speed things up.

- Foot Pressure sensor

- Thread tension sensor (The World of Dürkopp Adler Parts: How to measure the thread tension with a spring scale (sew24.blogspot.com))

- Height Adjusting tables

- Small quantity lines

- Seperate production plans which has small quantities in to a certain fixed set of lines with high / multi skilled operators such that these orders can be completed without impacting the main plant efficiency

- Reducing the time to changeover by improving the mechanics of the machine where repetitive actions need to take place

- Replace machine cover screws with magnets

- Reduction in screws

- Single turn screws

Buiding an Ecosystem

In building up a relationship with your ecosystem will benefit your company to;

- Utilize economies of scale to lower costs.

- Be quick to market with decentralized development arms

- Utilize matured knowledge and experience from experienced suppliers to lower your development and adoption time

Suppliers

- SSI SCHAEFER USA - A Global Leader in Intralogistics - Cutting-Edge Technologies Around the Globe! | SSI SCHAEFER (ssi-schaefer.com)

- SUPREME INTELLIGENT TECHNOLOGY CO.,LTD (china-supreme.com)

- SCHIPS AG sewing and ultrasonic technology made in Switzerland

- iSEW Sewing Studio - iSEW Sewing Studio Cape Town

- SiRUBA – Sewing Machine | KAULIN Official

- Agostoni

- Yamato Sewing Machine Mfg. Co., Ltd. :: Industrial Sewing Machines (yamato-sewing.com)

- SAGA PIN - Taiwan, China - Manufacturer - SAGAPIN - STD Fasteners -

- Shanghai Industrial Washing Equipment Manufacturer-Shanghai Weishi Machinery Co., Ltd. (shweishi.com)

- Guangzhou Keqi automation equipment Co.,Ltd (kekichina.com)

- Shanghai Hanfor Machinery Co., Ltd - seamless bonding machine, adhesive tape (alibaba.com)

- Hams Corporation?Kyoto Japan | Human Apparel Machine System (hams-jp.com)

- FOXSEW Sewing Machine, Cutting Machine manufacturer, Garment machine supplier, Special Sewing Machine manufacturer

- Norton Technology Solutions (nts.lk)

- Sensor Manufacturers, Suppliers, Factory - Customized Accessory - TZBOT (tzbotautomation.com)

- GRAND PRODUCTS (USA) GROUP (usa-grand.com)

- Packaging machines and packaging materials | Cyklop

- Guangqi sewing machines company (guanki.com)

- Electrical Sewing Machine Manufacturer,Automatic Sewing Machine Supplier,Exporter (guankiauto.com)

- KL 311 — English (pfaff-industrial.com)

- Textile Machinery | KARL MAYER

- Measuring & controlling running webs | Mahlo GmbH

- HOME | JINGONG INDUSTRIAL CO., LTD. (texabc.com)

- Braiding Machines and Winding Machines Manufacturer | VRK Group, Ahmedabad (narrowfabricmachinery.com)

- Sedo Treepoint | Experts for process optimization (sedo-treepoint.com)

- Shantou Hongji Machine Equipment Co., Ltd. - Laminating Machines, Bra Cup Machines (alibaba.com)

- Shantou Yili machine equipment Co., Ltd,www.yilicn.com.cn

Factory of the Future

Once your factory has the basics nailed down then you can consider the below automated solutions.

- Sewbo & US20150330018A1 - Facilitating the assembly of goods by temporarily altering attributes of flexible component materials - Google Patents

Robot Sewing Demonstration from Sewbo, Inc. from Sewbo on Vimeo.

- Electrical Sewing Machine Manufacturer,Automatic Sewing Machine Supplier,Exporter (guankiauto.com)

- Garment quality control - Shelton Vision

Building Support Structure

Mechanic Training

Your mechanics play a cruitial role in maintaining any automation that you introduce to your plant. It is important that these mechanics are elevated and motivated such that they are able to confidently upkeep automated solutions. The average mechanic on your production floor is able to perform basic sewing machine maintenance and machine setting but they need to be elevated such that they are able to handle and troubleshoot high tech machinery which will help your plant adopt new automations better.

A mechanic course could be structured as below.

|

Fundamental Course |

Intermediate Course |

Advanced Course |

|

|

Introduction |

Introduction to Mechanical Engineering

|

|

|

|

Introduction to Electrical/Electronic Engineering

|

|

|

|

|

Introdution to Mechatronic Engineering

|

|

|

|

|

Safety |

Workshop Safety

|

Workshop Safety

|

Workshop Safety

|

|

Personal Safety

|

Personal Safety

|

Personal Safety

|

|

|

Device Safety

|

Device Safety

|

Device Safety

|

|

|

Mechanical Engineering |

Machine Health and Safety

|

|

|

|

Component Selection

|

Advanced Mechanical Components

|

Material Selection

|

|

|

Reading Datasheets

|

|

|

|

|

Reading Drawings

|

|

|

|

|

Measuring tools and equipment

|

|

|

|

|

Fabrication tools and equipment

|

Fabrication tools and equipment

|

CNC Milling

|

|

|

CNC Turning

|

|||

|

Basic Design principles

|

|

|

|

|

|

Basic Solidworks Design

|

Complex Part Solidworks Design

|

|

|

|

Basic Solidworks Assembly

|

Complex Assembly Solidworks Design

|

|

|

Basic Manual Drawing

|

Basic Mechanical Drawing

|

|

|

|

|

Basic AutoCAD Design

|

Basic AutoCAD Design

|

|

|

|

|

Mechanical Simulations

|

|

|

|

|

Flow Simulations

|

|

|

|

|

CNC Coding

|

|

|

|

|

SolidCAM - laser cut

|

|

|

Electronic Engineering |

Safety

|

|

|

|

Fundamentals

|

|

|

|

|

Introduction to sensors and actuators

|

|

|

|

|

Introduction to prototyping

|

|

|

|

|

Basic Circuit Design

|

Useful Advanced Circuits

|

Useful Advanced Circuits

|

|

|

Reading Datasheets

|

|

|

|

|

Reading Schematics

|

|

|

|

|

Basic Module Selection

|

Selection of electronic components

|

Advanced Component Selection

|

|

|

Measuring tools and equipment

|

|

|

|

|

Fabrication tools and equipment

|

|

|

|

|

Debugging / Troubleshooting

|

Advanced Debugging

|

|

|

|

|

Debugging tools

|

|

|

|

Cable Selection / Management

|

|

|

|

|

|

PCB

|

|

|

|

|

Introduction to Technology

|

|

|

|

|

Proteus

|

NI Multisim

|

|

|

|

OrCAD

|

EasyEDA

|

|

|

Electrical Engineering |

|

Reading Schematics

|

|

|

|

Basic Circuit Design

|

|

|

|

|

Component Selection

|

|

|

|

|

Health and Safety

|

|

|

|

|

Motors

|

|

|

|

|

Cable Selection

|

|

|

|

|

Electrical Panel Boards

|

|

|

|

|

AutoCAD Electrical

|

|

|

|

|

Eagle

|

|

|

|

Programming |

PLC Introduction

|

Basic PLC Programming

|

Advanced PLC Programming

|

|

PLC Wiring

|

|||

|

PLC Troubleshooting

|

|||

|

Relay & Contactor Logic

|

|||

|

|

Basic HMI Programming

|

Advanced HMI Programming

|

|

|

|

Data Types

|

Advanced Data Types

|

|

|

|

Basic C Programming

|

PIC / Micro-controller Programming

|

|

|

|

Basic Arduino Programming

|

Intermediate Arduino Programming

|

|

|

|

PLC related Devices

|

Controlling Actuators

|

|

|

|

SCADA

|

3D Animation (Separate Course)

|

|

|

Robotics |

|

Introduction to Robotics

|

|

|

|

Robotic Applications

|

Robot Control

|

|

|

|

|

Robot Training

|

|

|

Pneumatics |

Introduction to Pneumatics

|

|

|

|

Safety

|

|

|

|

|

Basic Circuit Design

|

Pneumatic Calculations

|

|

|

|

Pneumatic Actuators

|

|

|

|

|

Reading & Drawing Schematics

|

|

|

|

|

Component Selection

|

|

|

|

|

Control Devices

|

|

|

|

|

Troubleshooting

|

|

|

|

|

6-Sigma Practices |

8 Step

|

|

|

|

TPM

|

TPM & WWBLA

|

TPM

|

|

|

Industrial Engineering |

Work Study Introduction

|

|

|

|

Method Study

|

|

|

|

|

Work Measurement

|

|

|

|

|

Basic Calculation in Work Study

|

|

|

|

|

Line Balancing

|

|

|

|

|

Utility |

Electrical Distribution

|

|

|

|

|

Air Compressor

|

|

|

|

|

Steam Boilers

|

|

|

|

General Engineering |

|

Design Thinking principles

|

Basic System Integration

|

|

|

Selecting & Sourcing electro-mechanical parts

|

Engineering Standards

|

|

|

Basic Project Management

|

Preparing Cost and Schedule

|

New Technology Introduction Process

|

|

|

Soft Skills |

Decision Making and Problem Solving

|

|

|

|

Communication and Language Development

|

|

|

|

|

IT Acumen

|

|

|

|

|

Personal Branding

|

|

|

|

|

|

Builds Performance Agility

|

|

|

|

|

Business Acumen

|

|

Game Changers

Automation alone is not always going to turn your plant around to be the best all around. You should always look in to the following.

- Create a world-class manufacturing team

- Radical re-Thiking capability

- Continuously challenge the status quo

- Mindset of nothing is enough

- Logical & systematic approach

- Manufacturing crossfunctional knowledge

- Thinking bandwidth

- Dynamic people

- World-class manufacturing facility and process

- Improve worker standard

- improve quality of the product (craftmanship)

- improve reliability of the delivery

- improve happiness index

- reduce cost of faliure

- improve agility with high quality

- Attract value added products /customers/ partnerships

- Best product at the best price

- Technology supported manufacturing

- Connected & data driven factory

- Multi-product/SOQ capability

- Eco-friendly manufacturing

- Going Global

- Mitigate country risk

- Duty advantage

- Support regional strategy

- Tap different capabilities

- Levering Lead time advantages - Supply chain